Auto Hole Cutting: Holes That Just Work

Creating holes for laser cutting shouldn't be manual work—especially when a single part has many joints or repeated connections.

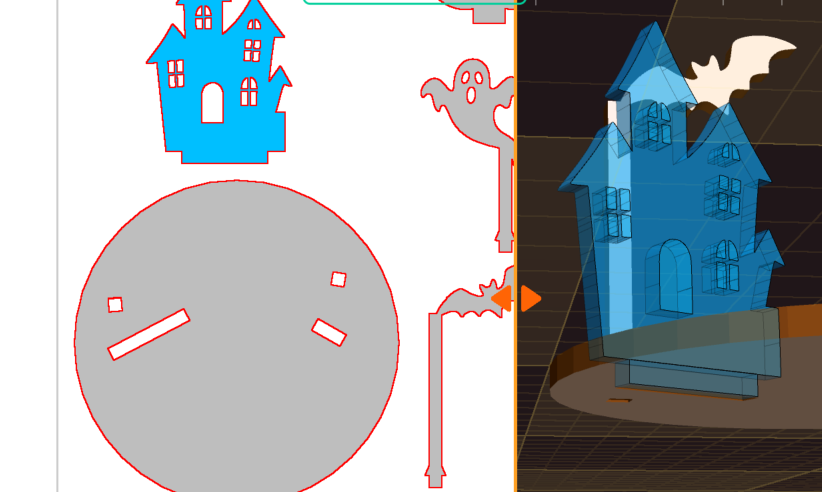

With Auto Hole Cutting in FlexCut3D, shapes can automatically create precise holes in other shapes when they intersect. There's no need to manually draw holes, align points, or manage extra cutter objects in your project.

How it works:

- Select a root shape

- Open the Auto Holes panel in the Properties panel

- Choose which shape should act as a hole cutter

- The cutter is added to the source shapes list

- Open the Flat Layout side panel to instantly see the result

That's it.

FlexCut3D automatically calculates the correct hole shape—even if the cutter is rotated or placed at an angle. Because laser cutters cut straight down, the system ensures every hole is calculated in a way that produces accurate, laser-ready results.

This is especially useful for parts with many joints, where manually creating, positioning, and managing holes would normally slow you down and clutter your project.

Clean projects. Fewer objects. Perfect fits.

Try Auto Hole Cutting in FlexCut3D

Launch AppQuestions? Contact us