FlexCut3D Update: Kerf Offset Control

We just rolled out a new update with Kerf Offset Control – a feature that makes compensating for laser beam width simple and visual.

What is Kerf?

When a laser cuts material, the beam itself has a physical width (the "kerf"). This means your cuts will be slightly larger than your design lines. For precision work, you need to compensate for this.

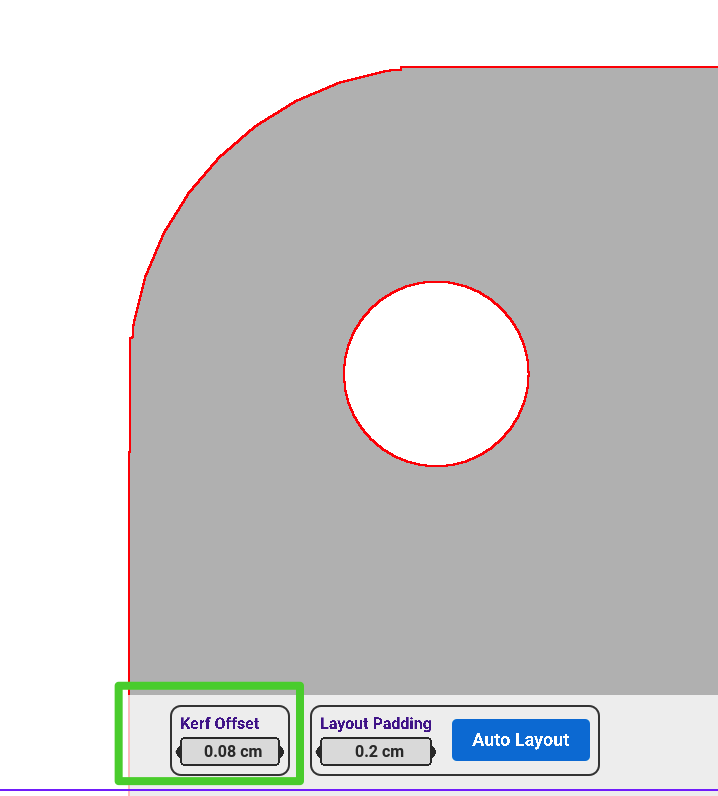

Drag the slider to see kerf compensation applied in real-time

How It Works

Measuring the exact diameter of your laser beam kerf has to be done manually through test cuts. Once you know your kerf width, FlexCat3D makes applying it easy:

- Use the Kerf slider to set your compensation amount

- Outer edges offset outward – parts get slightly smaller to account for material removal

- Inner cutouts offset inward – holes get slightly larger to maintain their intended size

- Drag back and forth to see the compensation in real-time in the Layout View

Why This Matters

Before kerf compensation, your assembled parts might have loose joints or tight holes. Now you can dial in the exact offset for your specific laser, and FlexCut3D automatically adjusts all edges correctly – outer edges go one direction, cutouts go the opposite.

Try it now in the latest version of FlexCut3D

Launch AppQuestions? Contact us